- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

Customer demand:

Customer demand:

Our company has recently successfully customized an efficient 10 ton feed pellet production line for a customer in the breeding business. The customer has achieved remarkable results in the feeding business, so there is an urgent need to improve the efficiency of feed production.

Solution:

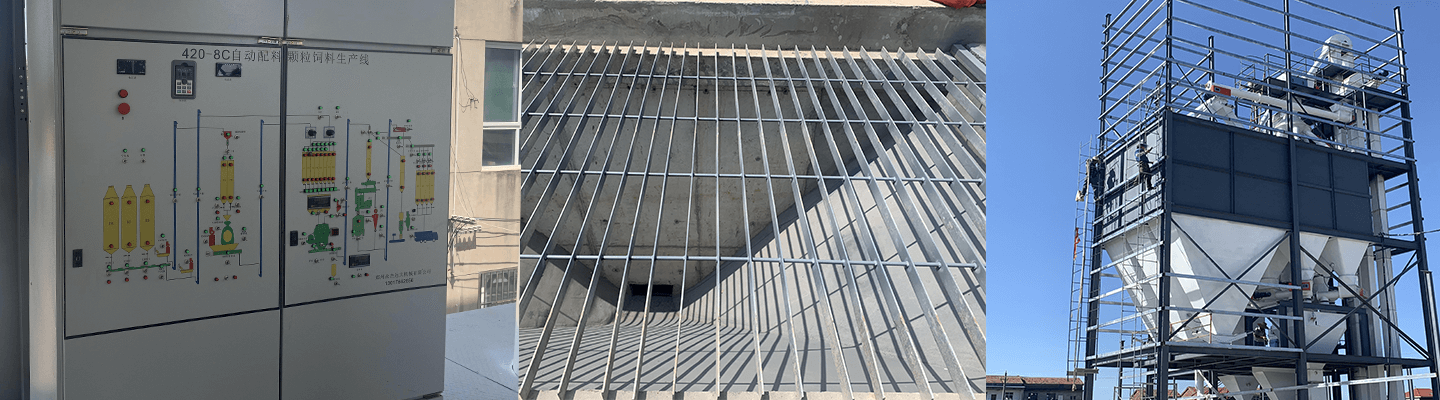

We designed a comprehensive feed pellet production line for the customer, in which the main machine is a 420 ring die pellet mill to ensure efficient and stable production. This pellet mill is known for its excellent performance and reliability, and is perfectly adapted to the requirements of large-scale feed production.

We deeply understood the customer’s site and height requirements, and designed a feed pellet production line to fit the actual site. In the site planning, we fully considered the customer’s production flow and equipment layout to ensure the smooth operation of the whole production line.

Site planning features:

. Flexible Layout: According to the site condition provided by the customer, we flexibly lay out the production line, making full use of every inch of space, ensuring the smooth connection between the equipment and improving the working efficiency.

. Height customization: In response to the customer’s height requirements, we adjusted the design of the equipment to ensure that the maximum degree of production efficiency is achieved in the limited vertical space to achieve the ideal height requirements.

. Safety Consideration: In the site planning, we focus on ensuring the safety of the work area, and reasonably set up access and emergency access to cope with emergency situations.

Mainframe selection: For the mainframe, we chose the 420 Ring Die Pellet Mill, whose excellent performance and reliability complemented the site plan. This machine not only meets the customer’s production requirements, but also works closely with the entire site plan to make the production line run more smoothly.

Results and benefits:

Through in-depth site planning and reasonable selection of the mainframe, we helped the customer realize an efficient, safe and flexible 10-ton feed pellet production line. The customer not only met the production demand, but also achieved the ideal production height within the limited site, which ultimately improved the overall production efficiency.

Summary:

While meeting the customer’s needs, we provided a complete set of customized solutions by taking into account the site and height requirements. We will continue to optimize the design and provide more advanced and reliable customized production lines to help our customers achieve greater success in their farming business.