- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

⚪Customization&OEM

⚪ Tailored Solutions, Customized Plans.

⚪Install with precision and expertise.

⚪Support throughout and beyond.

Product Introduction

This series of crusher is tangential feed hammer crusher, which can crush all kinds of dry feed, such as corn, sorghum, wall grain, straw, corn stalks, peanut vines, bean stalks, etc.

This series of crusher is simple in structure, high in production efficiency, easy to operate, reliable in use, easy to maintain, suitable for farms, livestock farms, various factories and rural industries, this machine can also crush Chinese herbal medicine, quartz, coal and coal dry stone, wood and so on, as raw materials for medicine and other industrial raw materials.

Application Area

Wood Chip Crusher Feed Crusher Feed Crusher Corn Crusher Grain Crusher It is the most ideal crushing equipment for all kinds of wood chips, straw, grass, culms, tree branches, waste cardboard, bamboo, wood shavings, corn stalks, peanut shells, straw, wood fuels, cotton stalks, biomass shells, corn, wheat and other miscellaneous grains and so on.

Working Principle

The machine adopts impact crushing method, utilizing the high-speed operation of the six movable hammers inside and the relative movement of the fixed tooth ring around, so that the materials are crushed through the impact, friction and mutual impact of the hammer teeth.

The crushed material passes through the screen under the action of rotating centrifugal force for screening, and then enters into the collection bag.

Product Parameters

| Model | 400 | 420 | 500 | 600 | 700 |

| Voltage(V) | 380V | 380V | 380V | 380V | 380V |

| Power | 5.5-7.5KW | 7.5-11KW | 15-18.5KW | 22 | 30 |

| Size | 0.86*0.62*0.85M | 1.15*0.75*0.9M | 1.55*0.82*1.1M | 1.55*0.83*1.1M | 1.65*1.3*1.35M |

| weight | 85KG | 120KG | 205KG | 280KG | 500KG |

| Capacity | 600-1000kg/g | 800-1500kg/g | 1000-2000kg/g | 2000-3000kg/g | 2500-4000kg/g |

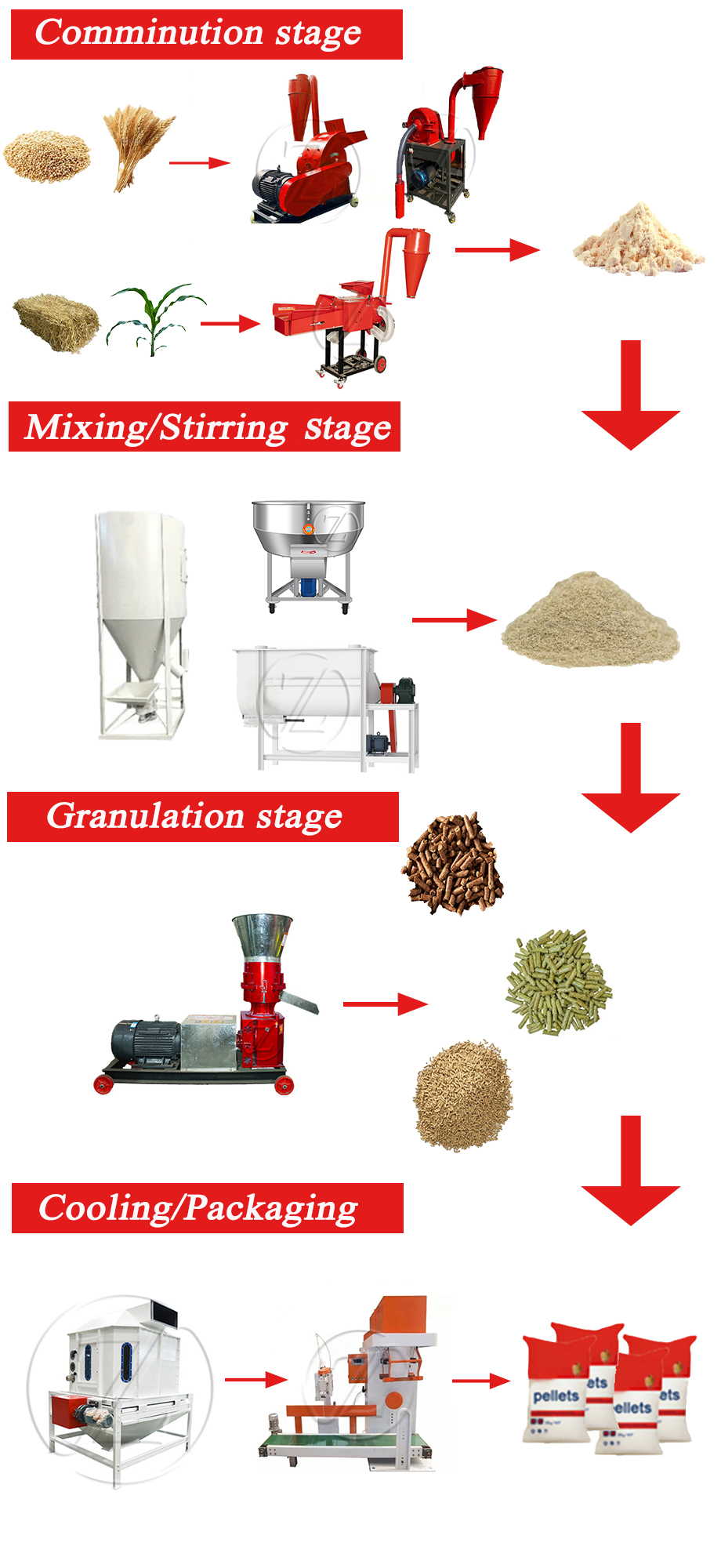

The production process of feed mill :

The Feed Milling Process typically involves the stages of raw material reception and storage, cleaning, crushing, dosing & mixing (batching), pelletizing, cooling, pellet refinement, screening & grading, packaging, and storage.

In specific cases where clients have unique requirements for feed pellet production equipment, additional features such as liquid infusion, curing, spraying, extrusion, drying, and more may be integrated.

Do you know the production process of a feed manufacturing plant?

Real Shot

Get An Instant Quotation For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Henan zhongzhenxing Machinery Equipment Co.,Ltd. Your dedicated partner in custom feed processing solutions. With a rich legacy spanning over a decade, we specialize in tailoring comprehensive equipment sets to meet the unique production needs of small, medium, and large-scale feed operations.