- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

⚪Customization&OEM

⚪ Tailored Solutions, Customized Plans.

⚪Install with precision and expertise.

⚪Support throughout and beyond.

Applicability of Feed Production Line:

Suitable for poultry, chickens, livestock, ruminants, cattle, sheep, pigs, goats, and more.

Questions Regarding the Chicken Feed Production Line:

1.Who is suitable for this chicken feed mill?

The chicken feed production line is specifically designed for breeders, farm owners, livestock enterprises, and feed processing plants.

2.What raw materials can be used in a chicken feed mill?

Raw materials for the chicken feed production line include corn, wheat, bran, soybean meal, fish meal, bone meal, and other ingredients such as vitamins, additives, premixes, salt, etc.

3.What kind of feed production line we can produce?

We can produce all kinds of feed pellets for meat rabbits, laying hens, bunny feed, cattle, pigs, ducks, sheep, poultry, livestock, goats and so on. Pellet size can be changed by adjusting the grinding tool to adapt to different animal livestock feeding needs.

4.What we can do for you?

We can provide services such as project design, process creation, installation and commissioning, as well as after-sales training. Our professional team is ready to offer comprehensive support at any stage of the feed production process.

Features of small feed pellet production line:

The production capacity of a small feed pellet plant ranges from 1 to 5 tons. Depending on your feed raw materials and specific requirements, you can choose between using a flat die pellet mill or a ring die pellet mill.

If you require smaller production capacity, a small-scale pellet plant is your ideal choice,It is suitable for individuals, business owners, small-scale farmers, small feed mills, and all startup enterprises.

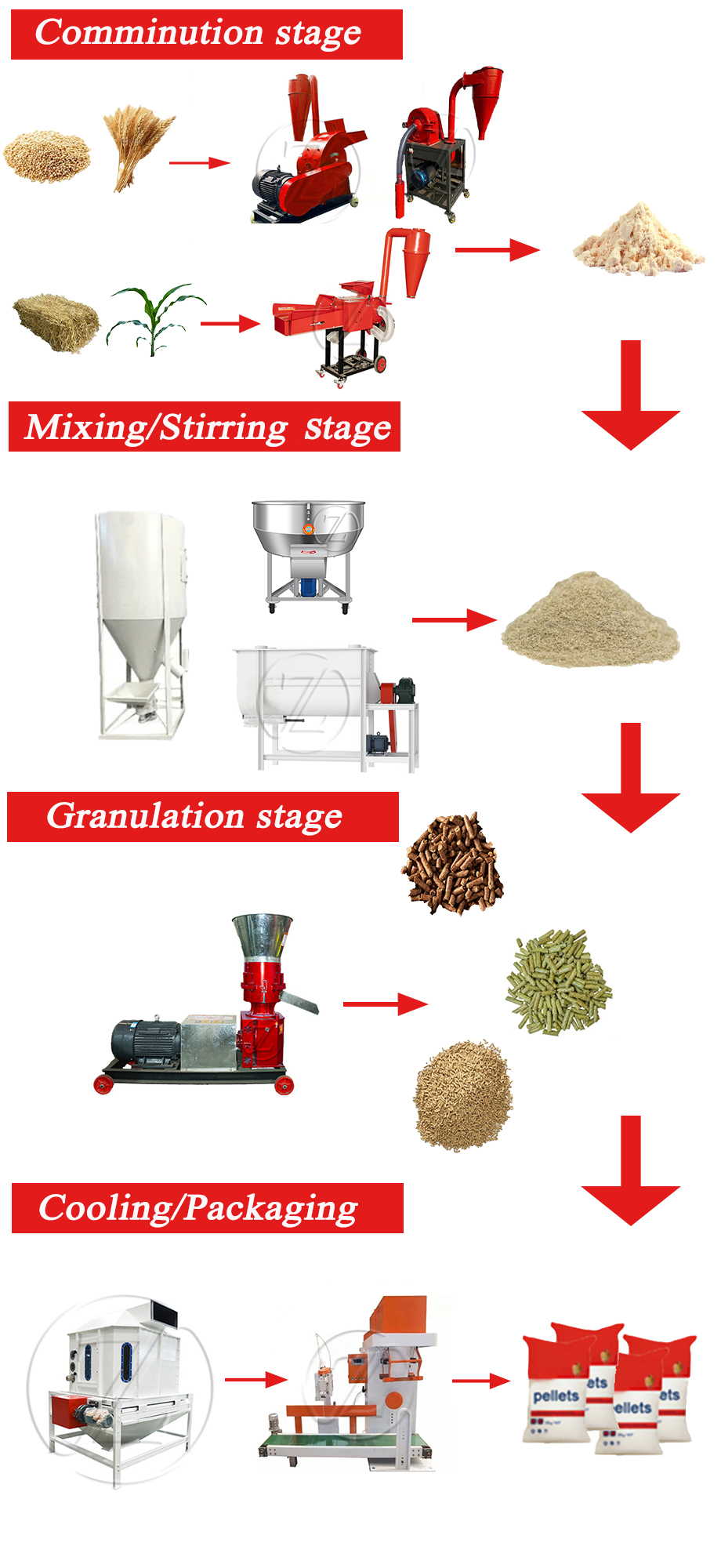

The production process of feed mill :

The Feed Milling Process typically involves the stages of raw material reception and storage, cleaning, crushing, dosing & mixing (batching), pelletizing, cooling, pellet refinement, screening & grading, packaging, and storage.

In specific cases where clients have unique requirements for feed pellet production equipment, additional features such as liquid infusion, curing, spraying, extrusion, drying, and more may be integrated.

Do you know the production process of a feed manufacturing plant?

Real Shot

Get An Instant Quotation For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Henan zhongzhenxing Machinery Equipment Co.,Ltd. Your dedicated partner in custom feed processing solutions. With a rich legacy spanning over a decade, we specialize in tailoring comprehensive equipment sets to meet the unique production needs of small, medium, and large-scale feed operations.