- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

⚪Customization&OEM

⚪ Tailored Solutions, Customized Plans.

⚪Install with precision and expertise.

⚪Support throughout and beyond.

Product Introduction

Pet food and traditional feeding methods have a great difference, this equipment with corn, soybean (bean cake) animal waste as raw materials, directly added into the machine can be expanded to produce different particles with novel shape, unique taste, rich nutrition, delicate organization, suitable for dog, cat, fish, bird, rabbit, shrimp, dog, cat, mink, fox and other pet tastes of feed.

Suitable for professional farmers, small and medium-sized feed mills and research institutions.

Product Parameters

| Model | Cutting motor | Feeding motor | Hourly output | Weight | Dimension |

| 40 | 0.4kw | 0.4kw | 40-60kg | 300 | 1.5*1.1*1.2 |

| 50 | 0.4kw | 0.4kw | 80-100kg | 320 | 1.55*1.1*2 |

| 60 | 0.4kw | 0.4kw | 120-160kg | 360 | 1.65*1.3*1.25 |

| 70 | 0.4kw | 0.4kw | 160-200kg | 450 | 1.65*1.3*1.25 |

| 80 | 0.4kw | 0.4kw | 260-300kg | 580 | 2.1*1.5*1.35 |

Suitable for professional farmers, small and medium-sized feed mills and research institution

Working Principle

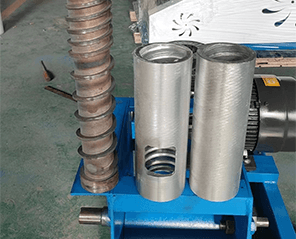

By extruding and pushing the unequal distance non-standard screw system of the feed expander, the gas in the material is discharged and quickly filled by the material.The material is subjected to shearing force and produces reflux, which increases the pressure in the machine bore. As the friction between the pile spinning and the chamber makes the material fully mixed, extruded, heated, glued and gelatinized, the original structure is damaged.Meanwhile, the mechanical energy is converted into heat energy through the friction of the material in the chamber, making the material into a liquid gelling state.When the material is extruded to the outlet, the pressure changes from high pressure to normal pressure and from high temperature to normal temperature.Cause the moisture quickly evaporates from the organizational structure, so that the internal formation of numerous microporous structure, and then through the cutting device, cutting cooling that extruded forming.

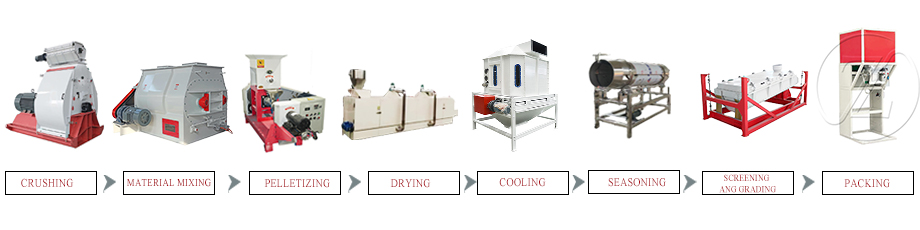

The production process of fish feed mill :

The aquafeed production line consists of seven main components: crusher, mixer, pelletizer, cooler, crusher, rotary grading sieve, and packaging. From raw material cleaning to processing and final pellet production, each step is carefully monitored and follows international standards. Our production line is suitable for processing a variety of livestock feeds, including those for pigs, cattle, sheep, chickens, ducks, and fish.

How is fish feed produced?

1.The feed hammer mill is employed for crushing raw materials.

We offer feed crushing machines with varying capacities to meet your diverse requirements. The small hammer mill is suitable for medium-sized feed extrusion plants, while the water drop hammer mill is designed for large to medium-sized aquatic feed factories. The micro-grinder is primarily used for the fine grinding of specialized aquatic feeds.

2.Feed Mixer → Used for Raw Material Blending

The feed mixer is widely employed in the production line of fish feed pellets for blending various grain powders. Mixing is one of the most crucial processes in aquatic feed production plants. The physical properties of feed ingredients are diverse, posing challenges of both mixing and separation. When adding materials to the feed mixer, smaller ingredients such as vitamins, minerals, and premixes of medications should be added later. Our mixer is designed with a U-shaped trough, dual shafts, and extended paddle blades, enhancing the length of the trough for uniform mixing of different materials in the shortest time possible (CV < 5%).

3. Fish Feed Pellet Extruder→For Fish Feed Pellet Extruding

During extrusion, the material undergoes high-temperature, high-moisture, and high-pressure cooking. At the moment of extrusion, the pressure drops suddenly, causing the water in the feed to turn from liquid to gas, resulting in material expansion, forming what is known as expanded feed. This type of feed not only shares the advantages of regular hard pellets, like good taste, prevention of grading, easy transportation, digestion improvement, and waste reduction, but also offers unique benefits. The high starch gelatinization in the feed enhances protein digestibility, improving animal feed utilization. It also exhibits excellent buoyancy, making it easy to observe fish feeding behavior and effectively controlling water pollution. These factors contribute to the widespread use of extruded feed.

4.Pellet Dryer → Drying Fish Feed Pellets

Fish feed pellets, post-extrusion, often contain 15-20% moisture, making them unsuitable for storage and market sale. The pellet dryer reduces moisture to around 10%, allowing for storage for over a year. It's an automatic dryer with advanced feeding and discharging mechanisms, featuring a customizable multi-layer design (3, 5, or 7 layers) and adjustable conveyor belt speed for controlling drying time.

5.Flavoring Machine → Sprays Oil onto Fish Feed Pellets

In fish or aquatic feed production, edible oil and heat-sensitive components are sprayed using a drum-type sprayer. As feed pellets enter the machine, gaseous and liquid materials are sprayed onto them, ensuring full contact between pellets and airborne droplets. The machine, with special nozzles, maximizes liquid atomization for even distribution on the pellet surface.

6.Pellet Cooler → Used for Cooling Fish Feed Pellets

After oil spraying, the fish feed pellets are conveyed to the counter-flow cooler. The pellet cooler in fish feed pellet processing offers advantages such as high automation, low air volume, low power consumption, and a small footprint.

7.Pellet Packaging Machine → Used for Packaging Fish Feed Pellets

This automatic packaging machine is designed for packaging fish feed pellets in bags weighing from 5 to 50kg. It ensures accurate weighing, reliable operation, and has a simple structure. The machine enables fast weighing and packaging of feed pellets.

Real Shot

Get An Instant Quotation For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Henan zhongzhenxing Machinery Equipment Co.,Ltd. Your dedicated partner in custom feed processing solutions. With a rich legacy spanning over a decade, we specialize in tailoring comprehensive equipment sets to meet the unique production needs of small, medium, and large-scale feed operations.