- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

⚪Customization&OEM

⚪ Tailored Solutions, Customized Plans.

⚪Install with precision and expertise.

⚪Support throughout and beyond.

Product Introduction

ZTIAS high level intelligent palletizer is a mechatronic technology product, which can complete the palletizing of various products such as bags, blocks, boxes, etc.

according to the required grouping and number of layers, and palletize the products on pallets according to a certain arrangement. This equipment adopts PLC+touch screen control to realize intelligent operation and management, which is easy to operate and master.

Wide-ranging Applications

It is suitable for palletizing operation of bagged goods in grain feed, chemical fertilizer, chemical industry, cement, flour and other industries.

Functional features:

Automatic palletizing of all kinds of bags, fast palletizing speed, neat palletizing, high degree of automation.

The equipment consists of belt feeder, shaper, palletizer (layering), automatic lifting (bag dumping mechanism) and other devices, the whole set of equipment is accurate and reliable. It is easy to maintain, save labor cost and improve the automation level of the enterprise.

Technical parameters:

|

Power

|

10.5kw |

|

Palletizing speed

|

400-600 packages/hour |

|

Palletizing height |

2.6m |

|

Palletizing method: |

five-flower palletizing, six-flower palletizing, seven-flower palletizing, eight-flower palletizing, ten-flower palletizing. |

|

Pressure |

0.3-0.6MPa |

|

Floor thickness

|

≥18 cm standard concrete

|

|

Floor space approx. |

20 square meters |

|

Dimension: |

4 meters long, 2.4 meters wide, 2.6 meters high. |

|

Product weight |

2700kg

|

|

Palletizing capacity |

600-800 packages/hour |

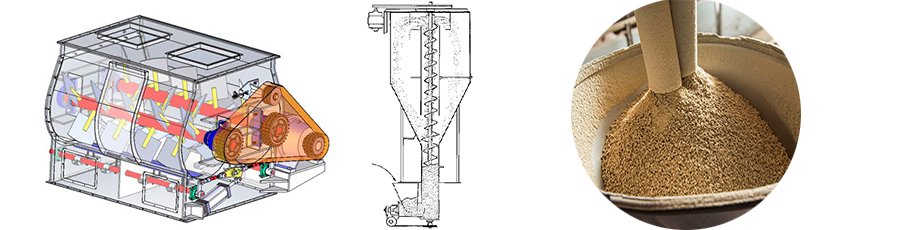

The production process of feed mill :

The Feed Milling Process typically involves the stages of raw material reception and storage, cleaning, crushing, dosing & mixing (batching), pelletizing, cooling, pellet refinement, screening & grading, packaging, and storage. In specific cases where clients have unique requirements for feed pellet production equipment, additional features such as liquid infusion, curing, spraying, extrusion, drying, and more may be integrated.

Do you know the production process of a feed manufacturing plant?

1.Raw material storage :

Given the diverse array of ingredients in animal feed, various types of silos are essential. The feed pellet production line can employ three types of silos, namely hopper silos, flat-bottom silos, and galvanized silos.

Primarily employed for eliminating impurities from feed raw materials, particularly large, medium, and ferrous impurities, aiming to achieve the following objectives:

○ Safeguarding both equipment and workers,○ Enhancing the quality of feed products, and ○ Ensuring secure and efficient equipment operation.

In accordance with the process flow and raw material composition of feed production, it is necessary to crush the raw materials to the required particle size.

4.Dosing equipment:

mainly used for dosing various raw materials, mixing materials evenly, including manual dosing type and automatic dosing type.

mix the feed ingredients thoroughly. This stage demands short blending cycles, high mixing quality, rapid discharge, low residue rates, excellent airtightness, and zero dust spillage.

6.Pellet Mill:

This process is to press out the pellets, the finished pellets are good palatability, storage resistance, there are two kinds of flat model and ring model, feed mills mainly use ring die pelletizing machine.

7.Cooling Equipment:

When pellets are extruded from the pellet machine, their moisture content reaches approximately 16%, and the temperature can reach 80-90 degrees Celsius. To facilitate pellet storage, the cooling process is indispensable.

8.Pellets Crusher / Breaker / Bucker :

Break the pellets into small particles.It is mainly used for chicken feed pellet line.

9.Screening Equipment:

After the pellet feed undergoes the crushing process, certain undesired materials such as powder are generated. This process primarily involves separating the non-conforming pellets and powder, allowing the qualified pellets to proceed to the next stage of production.

This includes both automatic packaging machines and manual packing machines.

11.Dust Removal Equipment:

Essential for eliminating dust and ensuring environmental protection.

12.Conveyor: for conveying feed ingredients, semi-finished and finished feeds

Get An Instant Quotation For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Henan zhongzhenxing Machinery Equipment Co.,Ltd. Your dedicated partner in custom feed processing solutions. With a rich legacy spanning over a decade, we specialize in tailoring comprehensive equipment sets to meet the unique production needs of small, medium, and large-scale feed operations.