- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

The new generation of livestock, poultry and aquatic feed production line was officially put into operation on 2021.2.1, marking further technological upgrading and innovation of ZTIAS in the field of feed production.

** Raw food receiving and cleaning section:**

The production line firstly filters out the large debris in the raw grain effectively by installing the feeding hopper with grate, which avoids the clogging phenomenon in the process of lifting and self-flow. Meanwhile, the application of cylinder cleaning sieve, powder cone cleaning sieve and strong iron removing permanent magnet cylinder guarantees the normal operation of the equipment and ensures the quality of feed.

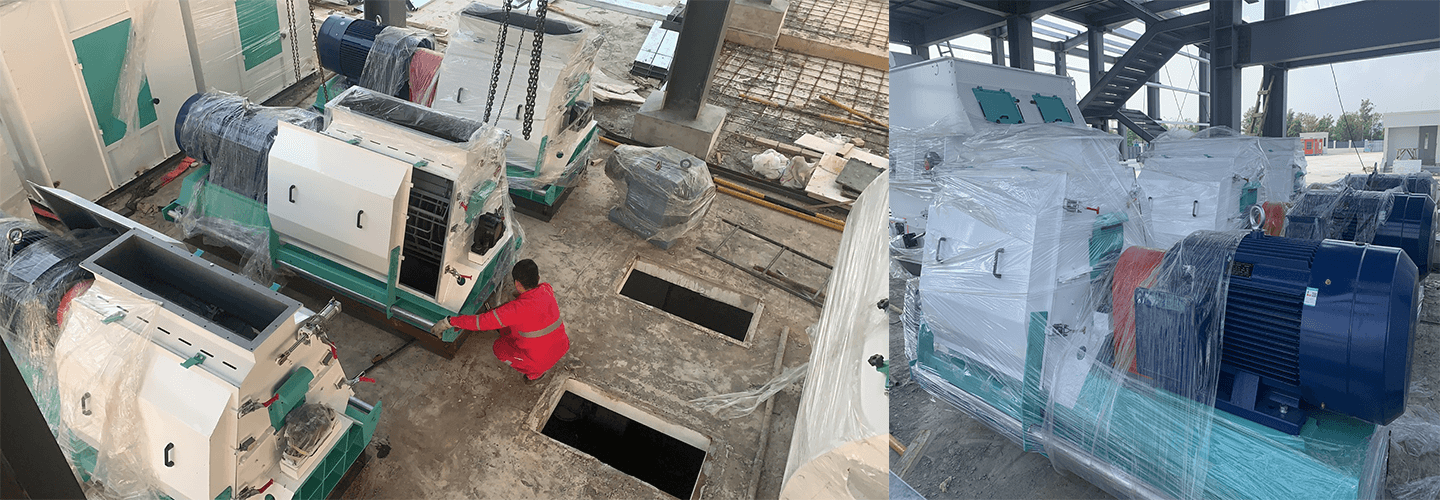

**Crushing section:**

Adopting advanced water drop type beyond-60*80 type pulverizer, the equipment is equipped with frequency conversion speed regulation impeller feeder, to ensure uniform feeding, pulverizer full workload. Down feed plus negative pressure pulse technology significantly improves the crushing efficiency, reduces dust and noise, especially suitable for crushing materials with fine particle size.

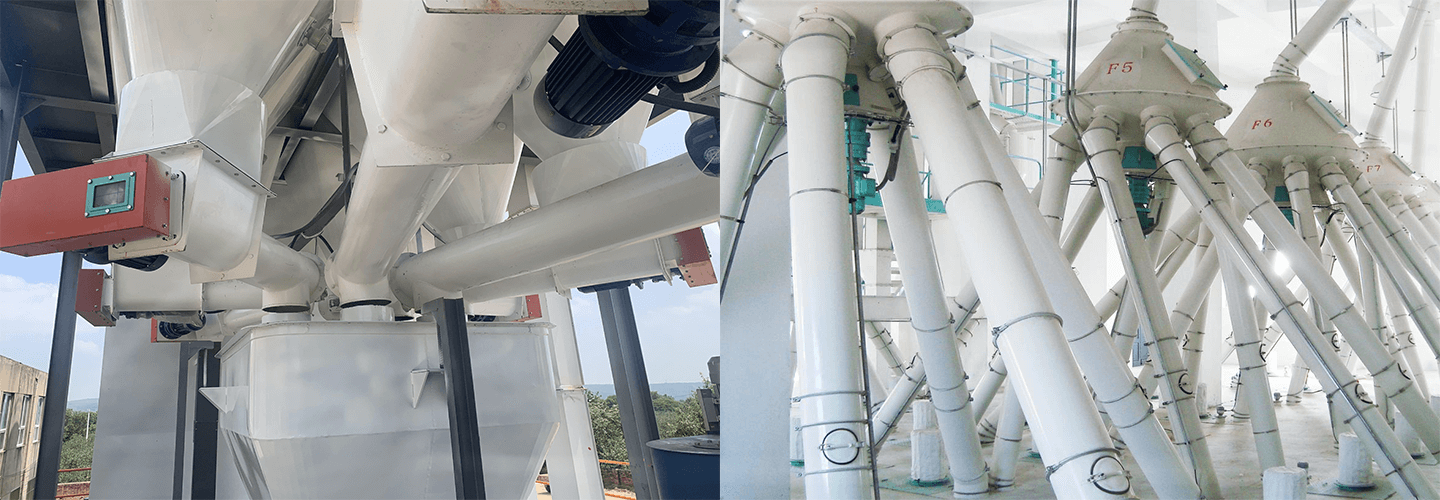

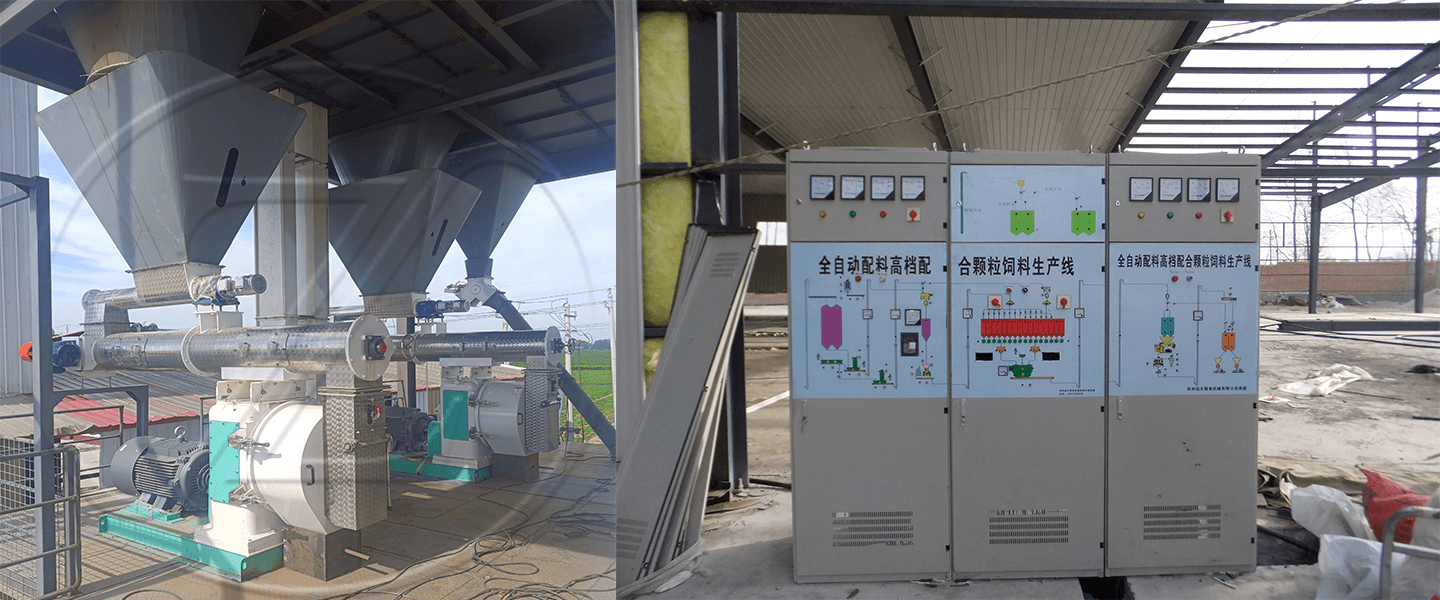

**Batching section:**

Using Taiwan Advantech industrial computer PLC full-screen control, with stable performance and high dosage accuracy. Automatic control of batching process, statistical batching report and equipped with rotary dispenser make the batching process more efficient and accurate, which greatly improves the production efficiency.

**Pelletizing section:**

Introducing new type SZLH420-110 granulator with stepless speed regulation for feeding and durable stainless steel shell. Direct drive, low noise, small energy consumption, to ensure efficient granulation.

**Cooling, crushing and screening section:**

SKLN20*20 counter-current cooler, SSLG15*150 roller granule crusher and SFJH130*2 plane rotary grading screen are adopted to ensure good cooling effect and superior screening effect.

**Dust removal system:**

The introduction of advanced and efficient multiple pulse dust collectors can effectively collect dust in the workshop, improve economic efficiency and improve the production environment.

**Dust removal system:**

The introduction of advanced and efficient multiple pulse dust collectors can effectively collect dust in the workshop, improve economic efficiency and improve the production environment.