- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

⚪Customization&OEM

⚪ Tailored Solutions, Customized Plans.

⚪Install with precision and expertise.

⚪Support throughout and beyond.

Introduction of SLHY Ribbon Mixer:

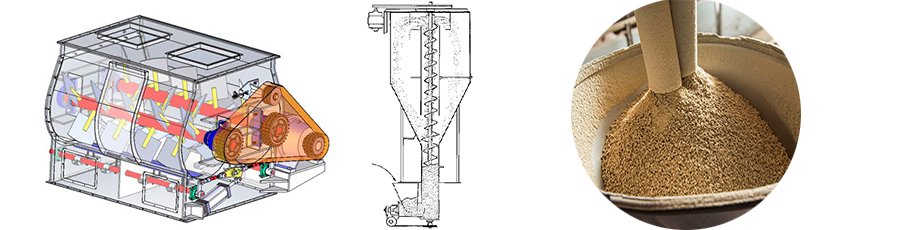

The SLHY Ribbon Mixer is a mixing equipment primarily used for uniformly blending different granular or powder materials.

It is characterized by the use of a helical ribbon agitator that rotates along the trough of the mixer, pulling and pushing materials from both directions to achieve efficient mixing.

Why use The SLHY Ribbon Mixer:

Uniform Mixing: The SLHY Ribbon Mixer employs a ribbon agitator to thoroughly pull and push materials during the mixing process, achieving a highly uniform blending effect.

Efficient Performance: The equipment utilizes a helical ribbon agitator, effectively enhancing mixing efficiency, reducing mixing time, and thereby increasing production efficiency.

Versatility for Various Materials: Due to its design features, the SLHY Ribbon Mixer is suitable for various granular or powder materials, demonstrating high versatility.

Prevention of Material Compression and Damage: The agitator design ensures the avoidance of material compression and damage during the mixing process, preserving the shape and quality of the materials.

Easy Cleaning and Maintenance: The equipment has a simple structure, facilitating easy cleaning and maintenance, contributing to improved reliability and extended equipment lifespan.

Wide Application: The SLHY Ribbon Mixer finds extensive application in industries such as food, chemical, and pharmaceuticals, catering to diverse mixing process requirements.

User-Friendly Operation: The operational process is relatively straightforward, requiring no complex skills and enhancing operational efficiency in the production line.

Technical Parameters

|

Model |

Power(kW) |

Output(kg/batch) |

Mixing Time(min) |

|

SLHY1 |

7.5 |

500 |

3-4 |

|

SLHY2.5 |

15 |

1000 |

3-4 |

Working Principle:

The working principle of the SLHY Ribbon Mixer relies on the unique design of the ribbon agitator, ensuring thorough mixing of materials while avoiding compression and damage.

This design is applicable to a variety of materials and finds widespread use in industries such as food, chemical, and pharmaceuticals.

The production process of feed mill :

The Feed Milling Process typically involves the stages of raw material reception and storage, cleaning, crushing, dosing & mixing (batching), pelletizing, cooling, pellet refinement, screening & grading, packaging, and storage. In specific cases where clients have unique requirements for feed pellet production equipment, additional features such as liquid infusion, curing, spraying, extrusion, drying, and more may be integrated.

Do you know the production process of a feed manufacturing plant?

1.Raw material storage :

Given the diverse array of ingredients in animal feed, various types of silos are essential. The feed pellet production line can employ three types of silos, namely hopper silos, flat-bottom silos, and galvanized silos.

Primarily employed for eliminating impurities from feed raw materials, particularly large, medium, and ferrous impurities, aiming to achieve the following objectives:

○ Safeguarding both equipment and workers,○ Enhancing the quality of feed products, and ○ Ensuring secure and efficient equipment operation.

In accordance with the process flow and raw material composition of feed production, it is necessary to crush the raw materials to the required particle size.

4.Dosing equipment:

mainly used for dosing various raw materials, mixing materials evenly, including manual dosing type and automatic dosing type.

mix the feed ingredients thoroughly. This stage demands short blending cycles, high mixing quality, rapid discharge, low residue rates, excellent airtightness, and zero dust spillage.

6.Pellet Mill:

This process is to press out the pellets, the finished pellets are good palatability, storage resistance, there are two kinds of flat model and ring model, feed mills mainly use ring die pelletizing machine.

7.Cooling Equipment:

When pellets are extruded from the pellet machine, their moisture content reaches approximately 16%, and the temperature can reach 80-90 degrees Celsius. To facilitate pellet storage, the cooling process is indispensable.

8.Pellets Crusher / Breaker / Bucker :

Break the pellets into small particles.It is mainly used for chicken feed pellet line.

9.Screening Equipment:

After the pellet feed undergoes the crushing process, certain undesired materials such as powder are generated. This process primarily involves separating the non-conforming pellets and powder, allowing the qualified pellets to proceed to the next stage of production.

This includes both automatic packaging machines and manual packing machines.

11.Dust Removal Equipment:

Essential for eliminating dust and ensuring environmental protection.

12.Conveyor: for conveying feed ingredients, semi-finished and finished feeds

Get An Instant Quotation For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Henan zhongzhenxing Machinery Equipment Co.,Ltd. Your dedicated partner in custom feed processing solutions. With a rich legacy spanning over a decade, we specialize in tailoring comprehensive equipment sets to meet the unique production needs of small, medium, and large-scale feed operations.