- Zhengzhou City, Henan Province China

- Telephone: 0086-16637162658

⚪Customization&OEM

⚪ Tailored Solutions, Customized Plans.

⚪Install with precision and expertise.

⚪Support throughout and beyond.

Product Introduction

Hot selling Manufacturer animal feed pellet processing equipment poultry farm feed factory fishpond pasture zoo pellet machine feed pellet processing machines.

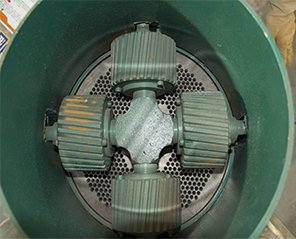

Working Principle

The spindle, driven by the motor, drives the press roll to rotate. The raw materials are ripened at high temperature between the press roll and the die plate. The particles are sent out of the machine from the die hole under the extrusion of the press roll.

The forming length of the particles is adjusted by the size of the aperture notch in the die plate. The natural ripening temperature is about 70 ℃. The particles formed by the granulation have smooth surface, high hardness and can be stored for a long time.

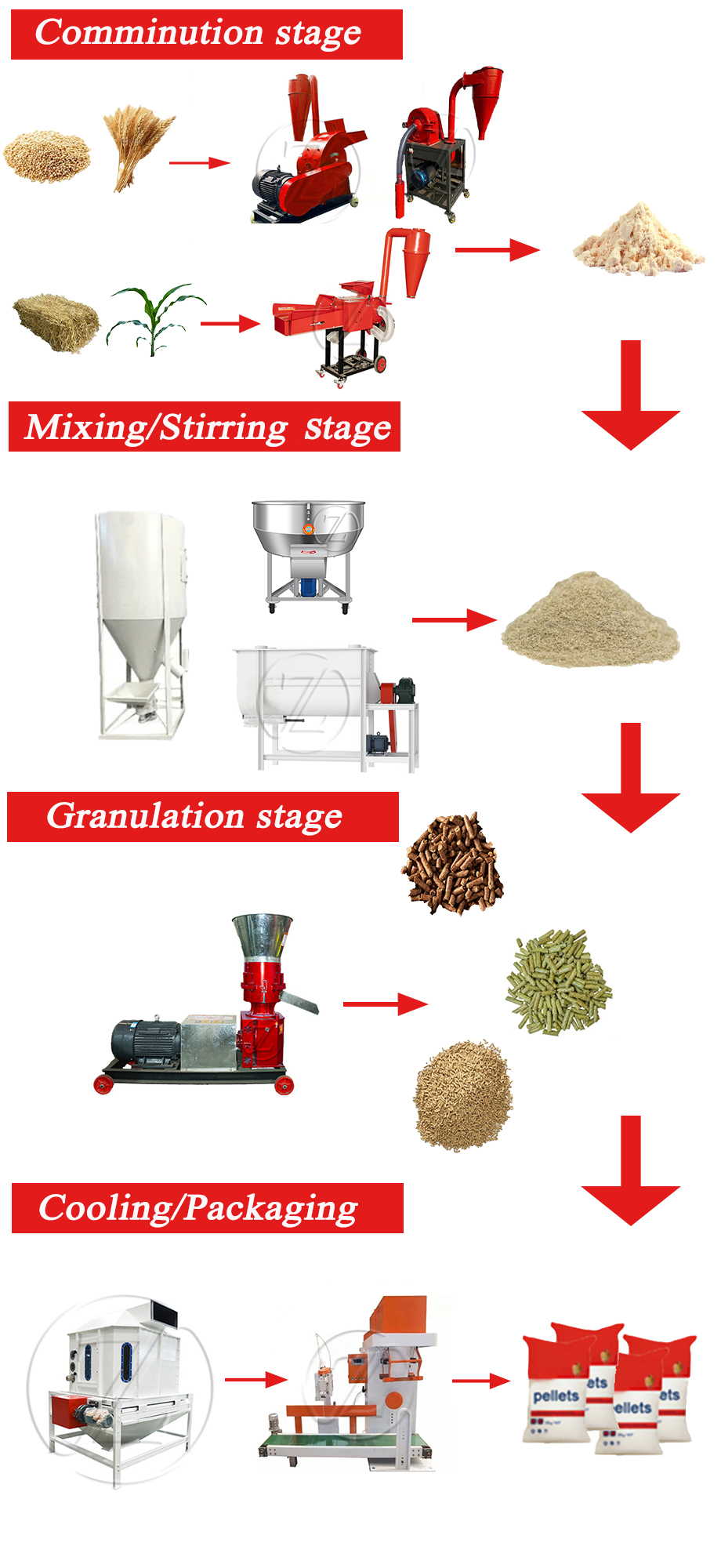

The production process of feed mill :

The Feed Milling Process typically involves the stages of raw material reception and storage, cleaning, crushing, dosing & mixing (batching), pelletizing, cooling, pellet refinement, screening & grading, packaging, and storage.

In specific cases where clients have unique requirements for feed pellet production equipment, additional features such as liquid infusion, curing, spraying, extrusion, drying, and more may be integrated.

Do you know the production process of a feed manufacturing plant?

Technical Parameters

|

Model |

Capacity(kg) |

Power(kw) |

Real Shot |

Details show |

|

|

150 |

150 |

4.5 |

-内容1-2.png) |

-内容2.png) |

-内容5.png) |

|

160 |

200 |

4.5 |

-内容1-2.png) |

-内容2.png) |

-内容4.png) |

|

180 |

250 |

4.5 |

-内容1-2.png) |

-内容2.png) |

|

|

210 |

350 |

7.5/11 |

-内容1.png) |

-内容2-1.png) |

-内容2-2.png) |

|

230 |

400 |

11 |

-内容1.png) |

-内容2.png) |

|

|

260 |

500 |

15 |

-内容1.png) |

||

|

300 |

1000 |

22 |

内容5.png) |

内容3.png) |

|

|

400 |

2000 |

37 |

内容1.png) |

内容1.png) |

|

Real Shot

Get An Instant Quotation For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.

Henan zhongzhenxing Machinery Equipment Co.,Ltd. Your dedicated partner in custom feed processing solutions. With a rich legacy spanning over a decade, we specialize in tailoring comprehensive equipment sets to meet the unique production needs of small, medium, and large-scale feed operations.